It was unable to encode logic, but was just a way to "connect the dots" where the programmer figured out many of the dots' locations longhand.

G-code began as a limited language that lacked constructs such as loops, conditional operators, and programmer-declared variables with natural-word-including names (or the expressions in which to use them). Some popular examples are Okuma's Advanced One Touch (AOT), Southwestern Industries' ProtoTRAK, Mazak's Mazatrol, Hurco's Ultimax and Winmax, Haas' Intuitive Programming System (IPS), and Mori Seiki's CAPS conversational software. Some CNC machines use "conversational" programming, which is a wizard-like programming mode that either hides G-code or completely bypasses the use of G-code.

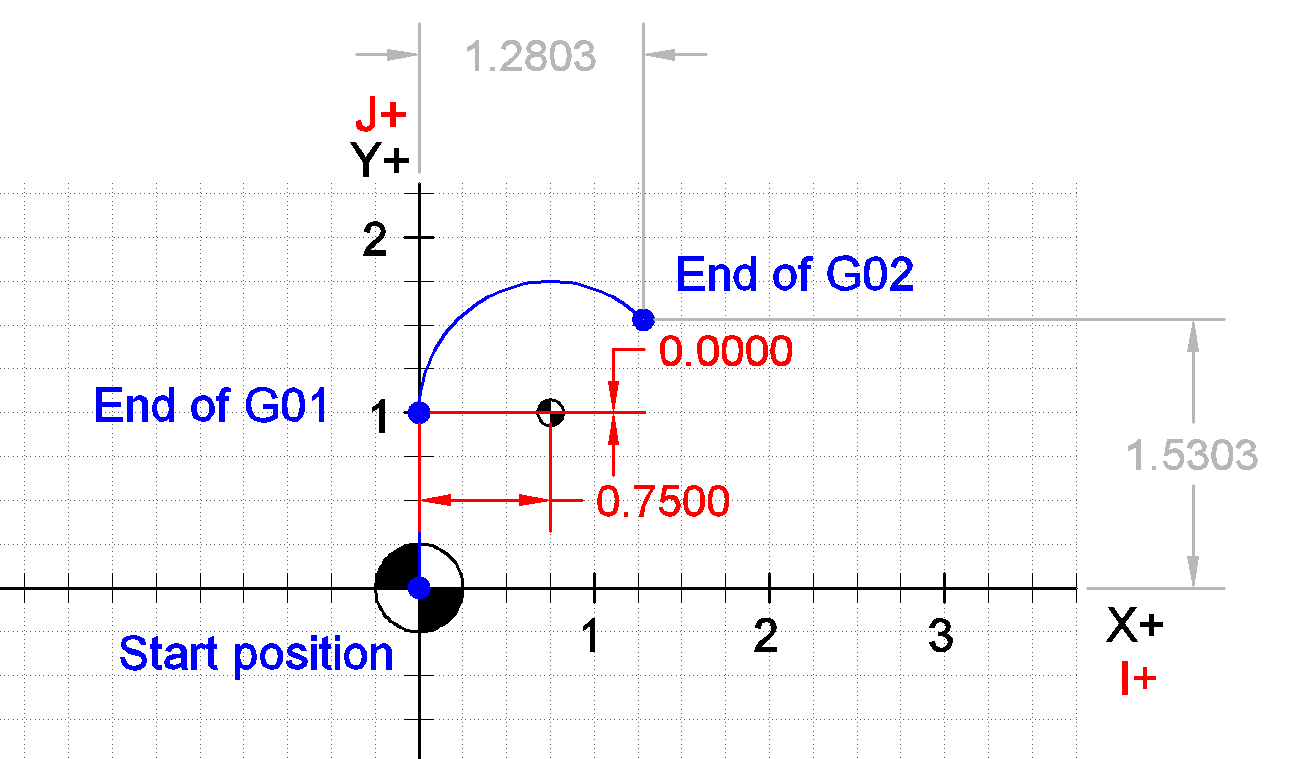

#G code zero axis software#

In the 2010s, controller differences and incompatibility are not as troublesome because machining operations are usually developed with CAD/CAM applications that can output the appropriate G-code for a specific machine through a software tool called a post-processor (sometimes shortened to just a "post"). Siemens was another market dominator in CNC controls, especially in Europe. ĭuring the 1970s through 1990s, many CNC machine tool builders attempted to overcome compatibility difficulties by standardizing on machine tool controllers built by Fanuc. Developed at MIT, BCL was developed to control CNC machines in terms of straight lines and arcs.

One standardized version of G-code, known as BCL (Binary Cutter Language), is used only on very few machines. For example, DIN 66025 is used in Germany, and PN-73M-55256 and PN-93/M-55251 were formerly used in Poland.Įxtensions and variations have been added independently by control manufacturers and machine tool manufacturers, and operators of a specific controller must be aware of differences of each manufacturer's product.

#G code zero axis iso#

In other countries, the standard ISO 6983 is often used, but many European countries use other standards. A final revision was approved in February 1980 as RS-274-D. The main standardized version used in the United States was settled by the Electronic Industries Alliance in the early 1960s. G-code has often been used in these implementations. In the decades since, many implementations have been developed by many (commercial and noncommercial) organizations. The first implementation of a numerical control programming language was developed at the MIT Servomechanisms Laboratory in the late 1950s. 5 Abbreviations used by programmers and operators.2.3 List of M-codes commonly found on FANUC and similarly designed controls for milling and turning.2.2 List of G-codes commonly found on FANUC and similarly designed controls for milling and turning.The same concept also extends to noncutting tools such as forming or burnishing tools, photoplotting, additive methods such as 3D printing, and measuring instruments. The two most common situations are that, within a machine tool such as a lathe or mill, a cutting tool is moved according to these instructions through a toolpath cutting away material to leave only the finished workpiece and/or an unfinished workpiece is precisely positioned in any of up to nine axes around the three dimensions relative to a toolpath and, either or both can move relative to each other. G-code instructions are provided to a machine controller (industrial computer) that tells the motors where to move, how fast to move, and what path to follow. It is used mainly in computer-aided manufacturing to control automated machine tools, and has many variants. G-code (also RS-274) is the most widely used computer numerical control (CNC) programming language.

Generally there is one international standard- ISO 6983. Many, mainly Siemens Sinumerik, FANUC, Haas, Heidenhain, Mazak.

0 kommentar(er)

0 kommentar(er)